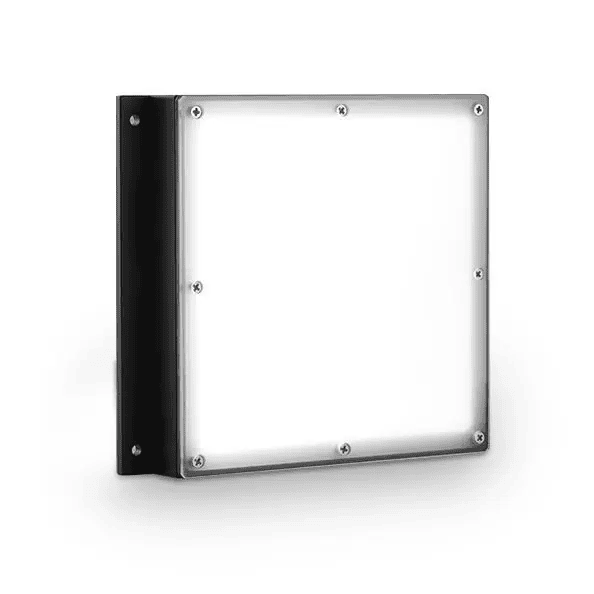

Surface Light / Square Light

The wavelength, dimensions, luminous intensity and other features can be customized for you. Welcome to contact!

EXAMPLES OF FEATURES AND PARAMETERS

| LED color | Red ( Infrared and ultraviolet are also available ) | White | Blue | Green |

| Wavelength & color temperature | 625nm | 6500±500K | 470nm | 525nm |

| Current (5±%) | 0.52A max | 0.33A max | 0.33A max | 0.33A max |

| Power (5±%) | 12.6W max | 7.92W max | 7.92W max | 7.92W max |

| Illuminance (WD:0mm) | 2361Lux | 4920Lux | 245Lux | 3985Lux |

| Input voltage | DC24V | |||

| Weight | 0.34KG (10±%) | |||

| Cable length | 2000mm (+0mm, -35mm) | |||

| Storage environment | Temperature: 0 ~ 40 ℃ , Humidity: 20 ~ 85% RH (non-condensing) | |||

Model

| Model | Color | Emitting Surface | Power |

| HS-SL-50-50 | R / G / B / W / IR / UV | 50mm*50mm | DC24V, 3W |

| HS-SL-100-100 | R / G / B / W / IR / UV | 100mm*100mm | DC24V, 6W |

| HS-SL-150-150 | R / G / B / W / IR / UV | 150mm*150mm | DC24V, 12W |

| HS-SL-200-200 | R / G / B / W / IR / UV | 200mm*200mm | DC24V, 20W |

| HS-SL-250-250 | R / G / B / W / IR / UV | 250mm*250mm | DC24V, 32W |

| HS-SL-300-300 | R / G / B / W / IR / UV | 300mm*300mm | DC24V, 48W |

| HS-SL-350-350 | R / G / B / W / IR / UV | 350mm*350mm | DC24V, 60W |

| HS-SL-400-400 | R / G / B / W / IR / UV | 400mm*400mm | DC24V, 80W |

| HS-SL-450-450 | R / G / B / W / IR / UV | 450mm*450mm | DC24V, 120W |

| HS-SL-500-500 | R / G / B / W / IR / UV | 500mm*500mm | DC24V, 135W |

| HS-SL-550-550 | R / G / B / W / IR / UV | 550mm*550mm | DC24V, 160W |

| HS-SL-600-600 | R / G / B / W / IR / UV | 600mm*600mm | DC24V, 200W |

DESCRIPTION AND APPLICATION SCENARIOS

-

- Suitable for inspection of appearance dimensions of precision parts, presence or absence of parts on mobile phone buttons, measurement of inner and outer diameters of oil tank cups, IC pin width and distance measurement.

- Suitable as a microscope stage to highlight the contour features of the object being measured. The high-density LED array provides high-brightness back lighting.

- Suitable for high-precision dimensional measurement, metal surface foreign matter detection, metal surface glue detection, glass container detection, screen positioning and fitting, optical fiber alignment, hardware product size measurement, spring spacing measurement, through hole inspection, mobile phone light guide plate detection, infusion device packaging inspection, audio water drop detection, shape detection of electronic components and ICs, film stain detection, and scratch detection of transparent objects

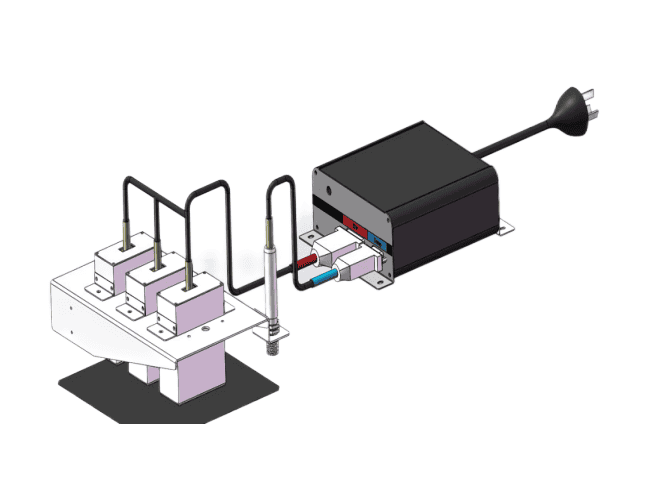

- Surface light sources are also called backlight sources. Usually, the light source is located between the camera and the workpiece. Front lighting is used to obtain the surface information of the workpiece by obtaining the reflection on the surface of the workpiece. The difference from general lighting is that when the backlight is used, the workpiece is usually located between the backlight and the lens, and the light passes through the head of the workpiece to obtain the workpiece information.

- The backlight or surface light source has high brightness, good directionality, and high uniformity illumination for a large area. It can be widely used in parallel backlight sources for high-precision, large-area product size measurement, various size measurements, transmission presence detection and other fields.

- It can add a brightness-enhancing film to the ordinary surface light to increase the brightness of the light source.

It has better light directivity and is more suitable for high-precision dimensional measurement.

The size is flexible and changeable, convenient for customer customization, and has a wide range of applications. and there is a variety of installation methods to facilitate customer installation, such as installed from three directions: front, back and side. - You can choose to suppress diffused light in specific directions, allowing the camera to receive more light and achieve a higher relative brightness than traditional backlights.

You can also choose to suppress the detection of irradiated light to achieve clear imaging of the edge of the workpiece, which is suitable for high-precision, arc-edge products. - When the light source works normally, it is glare of strong light so please do not look directly at the luminous area; it is recommended to use the light source controller produced by our company to control the switch and brightness of the light source through an external trigger or the internal software ; this is conducive to improving service life and brightness stability of the light source.